Umatshini wokusika imela ojikelezayo kabini ozenzekelayo

Umatshini wokusika imela ojikelezayo kabini ozenzekelayo

Malunga ne-duplex slitter

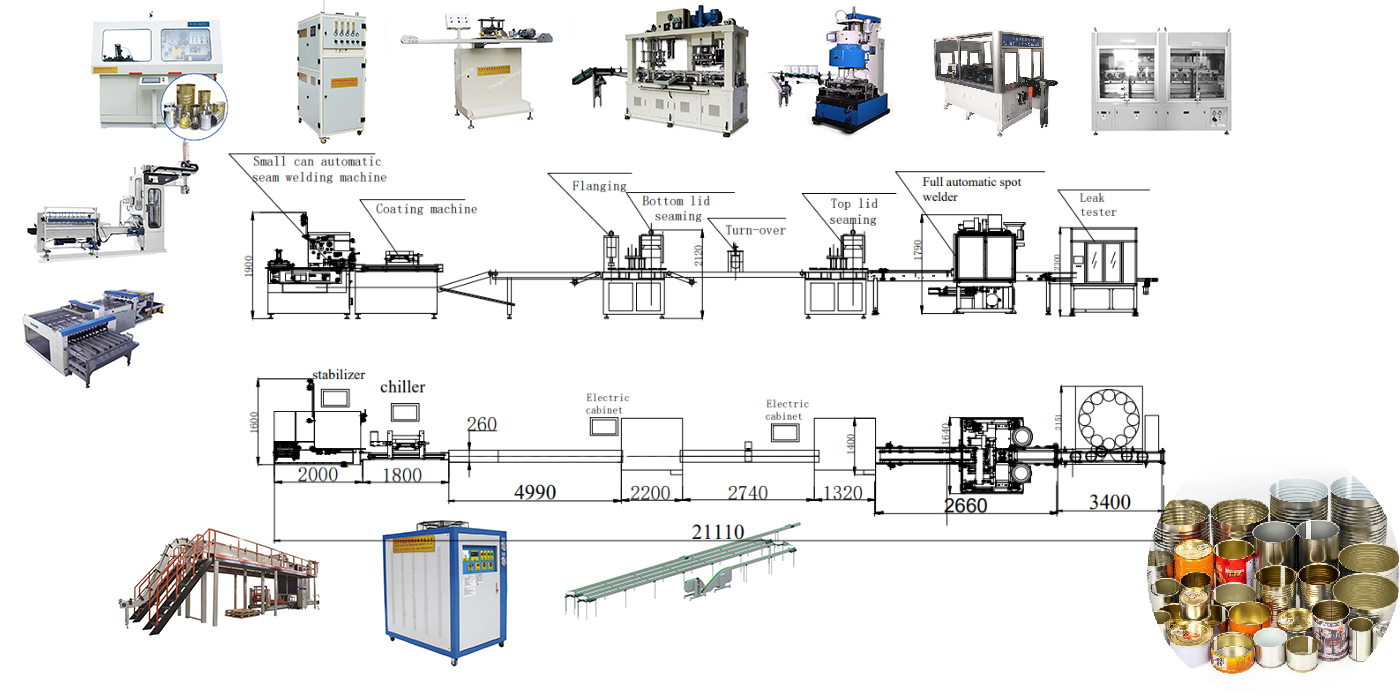

I-duplex slitter yenye yezona zixhobo zibalulekileyo kumgca wokuvelisa iitini eziziinxalenye ezi-3. Umatshini wokunqumla usetyenziselwa ukusika i-tinplate ibe ziindawo ezingenanto emzimbeni wetini ngobukhulu obuchanekileyo. I-duplex slitter yethu ikumgangatho ophezulu kwaye sisisombululo esifanelekileyo kumzi-mveliso wakho wokupakisha isinyithi.

Yenzelwe ngokukodwa iifektri zokutya ezisemathinini kunye nezityalo zokwenza iitini ezingenanto. Ikwafanelekile ukunqumla isinyithi sibe bukhulu obufanayo kwamanye amashishini, kwaye inokuhlangabezana neemfuno ezifunekayo zomatshini wokuwelda okhawulezayo.

I-slitter ine-feeder, i-shear, ibhokisi yokulawula yombane, i-vacuum pump, i-loader kunye ne-sharpener. I-slitter enemisebenzi emininzi inokusetyenziswa ngeendlela ezahlukeneyo, inokuyondla ngokuzenzekelayo, i-vertical, i-horizontal cutting ngokuzenzekelayo, i-duplex detection kunye ne-electromagnetism counting.

Ngamafutshane, i-automatic duplex slitter isebenza ngolu hlobo lulandelayo:

1. Ukufakwa kwePhepha ngokuzenzekelayo

2. Ukunqumla ngokuthe nkqo, Ukujika kunye nokubeka indawo, Ukunqumla ngokuthe tye

3. Ukuqokelela kunye nokubeka izinto ngokweemfumba

Ziqinile kakhulu, zenza kube lula ukulungelelanisa iifomathi ezahlukeneyo ezingenanto kwaye ziqinisekisa ukuchaneka okuphezulu kakhulu. Xa kufikwa kukuguquguquka, ukuchaneka, ukuthembeka kunye nesantya sokuvelisa, ii-slitters zethu zilungele kakhulu ukuvelisa i-tin canbody.

Iiparameters zobugcisa

| Ubukhulu bephepha | 0.12-0.4mm |

| Ubude bephepha kunye nobubanzi boluhlu lobungakanani | 600-1200mm |

| Inani leemicu zokuqala ezisikiweyo | 4 |

| Inani leemicu zesibini | 4 |

| Ububanzi bokusika kokuqala | 160mm-500mm |

| Ububanzi besikali sesibini | 75mm-1000mm |

| impazamo yobungakanani | Ubukhulu 0.02mm |

| Impazamo exwesileyo | Ubukhulu 0.05mm |

| ingxaki | ≤0.015mm |

| Isantya semveliso esizinzileyo | Amaphepha angama-30/ngomzuzu |

| amandla | Malunga ne-12Kw |

| Ukwamkelwa kusekelwe kwimigangatho yentsimbi yokuqala yeBaosteel okanye izinto ezilinganayo. | |

| Ukunikezwa Amandla | Intambo ezintlanu ze-AC ezinamanqanaba amathathu (ezinesiseko esisebenzayo kunye nesiseko esikhuselayo) |

| I-Voltage | 380V |

| I-voltage yesigaba esinye | 220V±10% |

| Uluhlu lwefrikhwensi | 49~50.5Hz |

| Ubushushu | ngaphantsi kwama-40°C |

| Umswakama | ngaphantsi kwe-80% |

Ulwazi oluthe kratya malunga ne-single slitter

I-slitter yephepha le-tinplate yindawo yokuqala yokwenza umgca weenkonkxa.

Isetyenziselwa ukusika ishiti ye-tinplate okanye ishiti yentsimbi engatyiwayo njengeembobo zomzimba ezinobukhulu obufunekayo okanye imicu yeziphelo zeetini. I-duplex slitter okanye i-single slitter zinokuguquguquka, zichanekile kwaye ziqinile.

Kumatshini wokunqumla omnye, ufanelekile ukwahlukanisa nokusika imicu, kwaye kumatshini wokunqumla imicu emibini, ukusika ngokuthe tye kunye nokusika ngokuthe nkqo. Xa umatshini wokucheba i-tinplate usebenza, umsiki ophezulu kunye nomsiki osezantsi ziqengqeleka kumacala omabini eeshiti zesinyithi eziprintiweyo nezifakwe i-lacquer, ubungakanani bezixhobo zokunqumla busekelwe kwinani leemicu kunye neefomathi ezingenanto. Umgama phakathi komsiki ngamnye kulula kwaye kuyakhawuleza ukuwulungisa, ngoko ke uhlobo lomatshini wokusika i-tinplate lubizwa ngokuba yi-gang slitter okanye umatshini wokunqumla imicu. Umsiki we-carbide uyafumaneka kumenzi we-can.

Ngaphambi komatshini wokunqumla kabini okanye umatshini wokunqumla omnye, i-automatic sheet feeder ixhotyiswe ukufunxa nokuhambisa i-tinplate ngokufunxa idiski enenkqubo ye-pneumatic kunye nesixhobo sokufumanisa amaphepha amabini. Emva kokucheba, umqokeleli kunye ne-stacker banokukhupha ngokuzenzekelayo, kwaye ukudluliselwa phakathi kwe-slitter kunye ne-canbody welder nako kuyafumaneka.

Isantya esiphezulu kunye nezinto ezincinci zifuna ukuchaneka okuphezulu kunye nomphezulu oqaqambileyo. Amaphepha ahlala ekhokelwa. IiConveyors ziqinisekisa ukuba iphepha, umgca kunye nokuthuthwa okungenanto kuthambile kwaye kukhuselekile. I-slitter enye ingagqitywa ngokusika okwesibini; ngoko ke utyalo-mali kwi-slitter enye lutyalo-mali oluxabisekileyo ukuba imveliso ye-canbody icetyelwe ukuba yonyuswe. Kulula ukuyigcina nokuyisebenza. Yeyokusika imicu okanye nje ukucheba amaphepha. Iyafumaneka kwi-tinplate okanye kwiishiti ze-aluminium.