eyona nkqubo iphambili yemveliso yomzimba wetoti yokutya eneziqwenga ezintathu

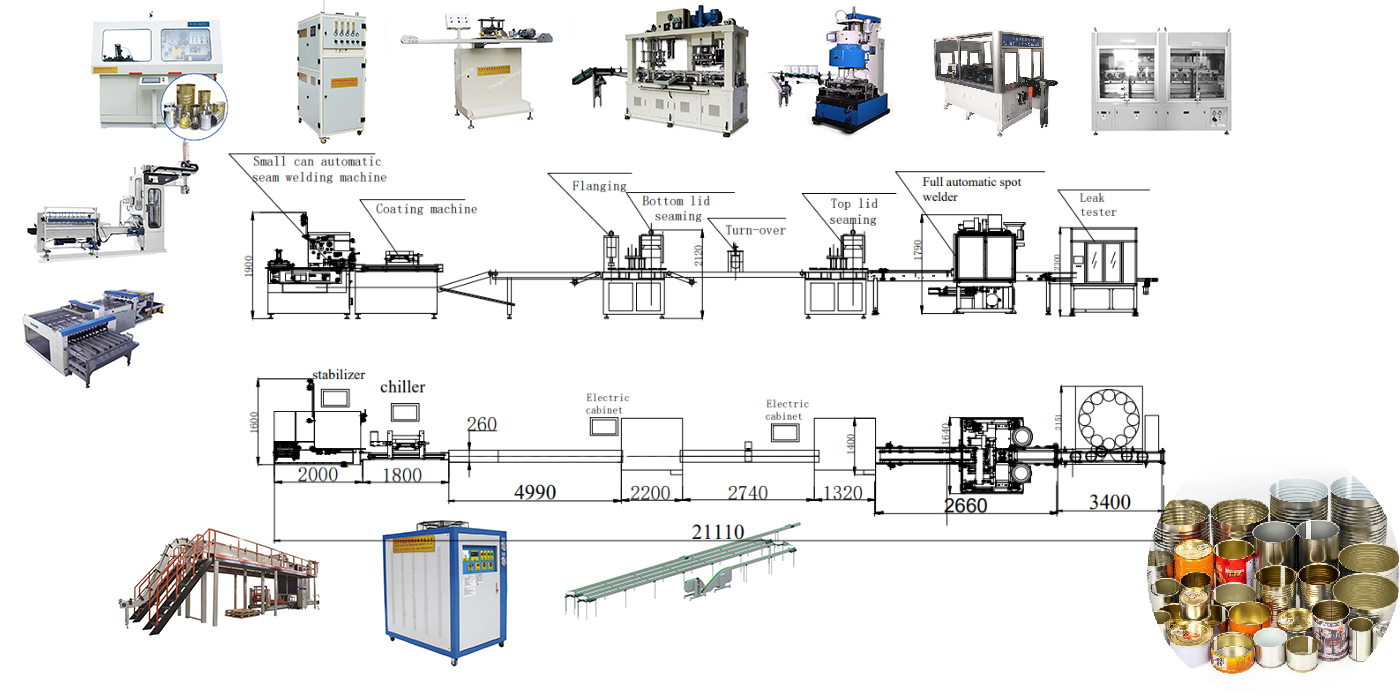

Inkqubo ephambili yokuvelisa umzimba wezinto ezintathu zokutya zingabandakanyaukusika, ukuwelda, ukutyabekakwayeukomisaUmthungo we-weld, intamo, i-flanging, i-beading, ukutywinwa, uvavanyo lokuvuza, ukutshiza ngokupheleleyo kunye nokomisa, kunye nokupakishwa. E-China, umgca we-automatic can production ngokuqhelekileyo uqulunqwe ngoomatshini bokuhlanganisa umzimba, oomatshini bokucheba be-bi-directional, oomatshini be-welding, ukukhuselwa komthungo we-weld kunye ne-coating / ukunyanga iinkqubo, iinkqubo zangaphakathi zokutshiza / zokunyanga (ukhetho), oomatshini bokubona ukuvuza kwe-intanethi, umatshini ongenanto wokupakisha, oomatshini bokubopha, kunye nefilimu yokusonga / ukufudumala koomatshini. Okwangoku, umatshini wokuhlanganisa umzimba unokugqiba iinkqubo ezifana nokuqhawula, ukubopha intamo, ukwandisa, ukuvutha, ukuvutha, ukubethelwa, ukuthunga okokuqala kunye nesibini, ngesantya esifikelela kwi-1200 iinkonkxa ngomzuzu. Kwinqaku elidlulileyo, sachaza inkqubo yokuqhawula; ngoku, makhe sihlalutye inkqubo yentamo:

Ukuqhokra

Enye indlela ebalulekileyo yokunciphisa ukusetyenziswa kwezinto eziphathekayo kukunciphisa i-tinplate. Abavelisi be-tinplate benze umsebenzi obalulekileyo kulo mba, kodwa ukucutha i-tinplate ukunciphisa kunokunciphisa iindleko zokumelana noxinzelelo lwesakhiwo setoti, kwaye amandla ayo ngoku ancinci kakhulu. Nangona kunjalo, ngenkqubela phambili kwi-necking, i-flanging, kunye nokwandisa itekhnoloji, kuye kwakho impumelelo emitsha ekunciphiseni ukusetyenziswa kwezinto, ngakumbi kumzimba wetoti kunye nesivalo.

Inkuthazo ephambili yokuvelisa iitoti ezinentamo ekuqaleni yayiqhutywa ngumnqweno wokuphuculwa kwemveliso ngabavelisi. Kamva, kwafunyaniswa ukuba ukubopha umzimba wetoti yindlela esebenzayo yokugcina izinto. I-Necking inciphisa i-diameter yesiciko, ngaloo ndlela inciphisa ubungakanani obungenanto. Ngexesha elifanayo, njengoko amandla e-lid enyuka kunye nobubanzi obuncitshisiweyo, izinto ezincinci zinokufezekisa ukusebenza okufanayo. Ukongeza, amandla ancitshisiweyo kwisiciko avumela indawo encinci yokutywina, ngakumbi ukunciphisa ubungakanani bokuvala. Nangona kunjalo, ukuncipha kwesixhobo somzimba kunokubangela imiba ngenxa yotshintsho kuxinzelelo lwezinto eziphathekayo, njengokunciphisa ukuxhathisa ecaleni kwe-axis kunye ne-can body cross-section. Oku kwandisa umngcipheko ngexesha leenkqubo zokuzaliswa koxinzelelo oluphezulu kunye nokuthutha ngabafaki kunye nabathengisi. Ke ngoko, ngelixa intamo inganciphisi kakhulu imathiriyeli yetoti yomzimba, ikakhulu igcina imathiriyeli esicikweni.

Ngenxa yempembelelo yale miba kunye nemfuno yeemarike, abaninzi abavelisi baye baphucula kwaye baphucula iteknoloji yentamo, ukuseka indawo yayo ekhethekileyo kwizigaba ezahlukeneyo zokuvelisa.

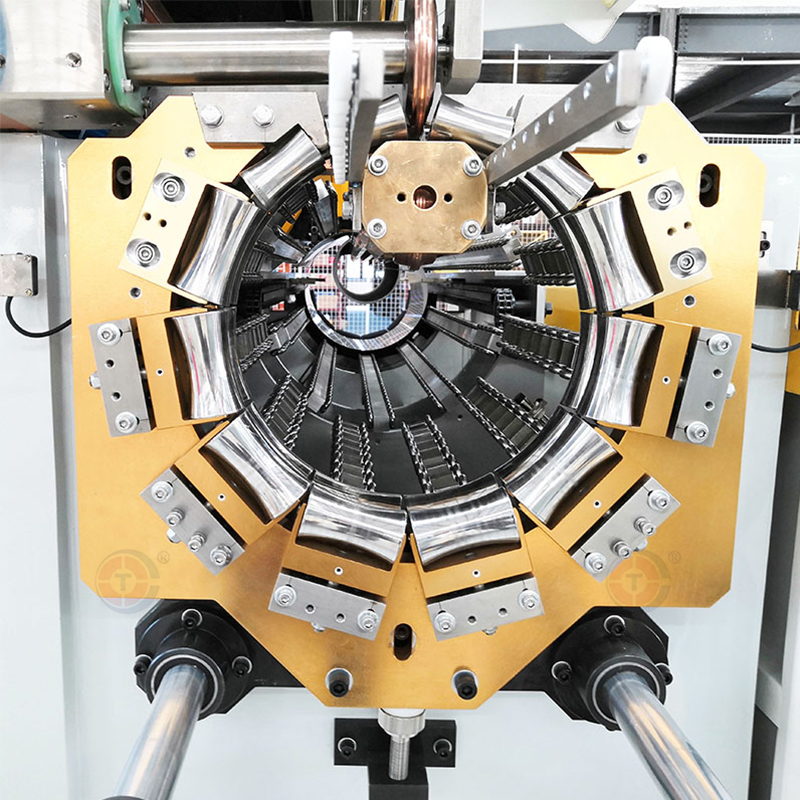

Ukungabikho kwenkqubo yokuqhawula, intamo yinkqubo yokuqala. Emva kokutyabeka kunye nokunyanga, umzimba wetoti uhanjiswa ngokulandelelana kwisikhululo sentamo ngumbungu wokwahlula kunye nevili lenkwenkwezi. Kwindawo yokudlulisa, i-mold yangaphakathi, elawulwa yikhamera, i-axially ihamba emzimbeni we-can ngelixa ijikeleza, kunye ne-mold yangaphandle, ekhokelwa yi-cam, idla ide ihambelane ne-mold yangaphakathi, igqibe inkqubo yentamo. Umngundo wangaphandle emva koko ukhuphe kuqala, kwaye umzimba unako uhlala kubumba lwangaphakathi ukunqanda ukutyibilika de ufikelele kwindawo yokudluliselwa, apho ukhuphela ukungunda kwangaphakathi kwaye uhanjiswe kwinkqubo yeflanging ngevili lenkwenkwezi ephumayo. Ngokuqhelekileyo, zombini iindlela ze-symmetric kunye ne-asymmetric necking zisetyenziswa: yangaphambili isetyenziselwa i-202-diameter can, apho zombini iziphelo zihamba ngentamo ye-symmetric ukunciphisa ububanzi ukuya kwi-200. Le yokugqibela inokunciphisa enye isiphelo se-202-diameter can ukuya kwi-200 kunye nesinye isiphelo ukuya kwi-113, ngelixa i-202 ye-can be-diameter, i-202, i-292, i-202, i-202, i-202, i-202, i-202, i-202-diameter, kunye ne-202-diameter. emva kwemisebenzi emithathu ye-asymmetric necking.

Kukho itekhnoloji ezintathu eziphambili zentamo

- Intamo yokungunda: I-diameter yomzimba yetoti inokucutheka kwelinye okanye zombini iziphelo ngaxeshanye. Idayamitha kwelinye icala lomsesane wentamo ilingana nedayamitha yoqobo yetoti yomzimba, kwaye esinye isiphelo silingana nedayamitha yentamo efanelekileyo. Ngexesha lokusebenza, iringi yentamo ihamba ecaleni kwe-axis yomzimba, kwaye ukungunda kwangaphakathi kunqanda ukushwabana ngelixa uqinisekisa intamo echanekileyo. Isitishi ngasinye sinomda wokuba ingakanani i-diameter ingancitshiswa, ngokuxhomekeke kumgangatho wezinto eziphathekayo, ubukhulu, kunye ne-diameter. Ukunciphisa ngalunye kunokunciphisa ububanzi malunga ne-3mm, kwaye inkqubo ye-necking ye-multi-station inokunciphisa nge-8mm. Ngokungafaniyo neetoti ezimbini, iitoti ezintathu azifanelekanga ukuphindaphinda i-mold necking ngenxa yokungahambelani kwezinto eziphathekayo kwi-weld seam.

- I-Pin-elandela intamo: Le teknoloji ithathwe kwimigaqo-emibini ye-necking ye-necking. Ivumela iigophe zejometri ezigudileyo kwaye inokwamkela i-necking yamanqanaba amaninzi. Umthamo wentamo unokufikelela kwi-13mm, kuxhomekeke kwizinto eziphathekayo kwaye unobubanzi. Inkqubo yenzeke phakathi kwe-mold yangaphakathi ejikelezayo kunye ne-mold yangaphandle eyenza i-mold, kunye nenani lokujikeleza ngokuxhomekeka kwixabiso lentamo. Izithinteli ezichanekileyo ziqinisekisa ukugxila kunye nokuhanjiswa kwamandla e-radial, ukuthintela ukuguqulwa. Le nkqubo ivelisa iigophe zejometri ezifanelekileyo kunye nokulahleka kwezinto ezincinci.

- Ukubumba umngundo: Ngokwahlukileyo kwintamo yokubumba, i-can body yandiswa ukuya kububanzi obufunwayo, kwaye i-mold forming ingena ukusuka kwiziphelo zombini, ibumba i-curve yokugqibela yentamo. Le nkqubo yenyathelo elinye inokufezekisa iindawo ezigudileyo, kunye nomgangatho wezinto eziphathekayo kunye nengqibelelo ye-weld seam emisela umehluko wentamo, onokufikelela kwi-10mm. Ukubumba okufanelekileyo kunciphisa ubukhulu be-tinplate nge-5%, kodwa bugcina ubungqimba entanyeni ngelixa uphucula amandla onke.

Ezi teknoloji ezintathu ze-necking nganye zibonelela ngeenzuzo ngokuxhomekeke kwiimfuno ezithile zenkqubo yokuvelisa.

IVidiyo eNxulumeneyo yeTin Can Welding Machine

I-Chengdu Changtai Intelligent Equipment Co., Ltd.- Isixhobo esizenzekelayo sinakho uMenzi kunye noMthumeli ngaphandle, ubonelela ngazo zonke izisombululo zeTin enokwenza. Ukwazi iindaba zamva nje zeshishini lokupakisha isinyithi, Fumana i-tin entsha inokwenza umgca wemveliso, kwaye ufumane amaxabiso malunga noMatshini wokwenza, khetha uMgangatho wokwenza uMatshini e-Changtai.

Qhagamshelana nathingeenkcukacha zoomatshini:

Umnxeba: +86 138 0801 1206

Whatsapp: +86 138 0801 1206 +86 134 0853 6218

Email:neo@ctcanmachine.com CEO@ctcanmachine.com

Ixesha lokuposa: Oct-17-2024