Indima ye-Welding Advanced kunye ne-Slitting Machine kwi-Tin Can Manufacturing

Ekupakishweni kokutya kunye nesiselo, iinkonkxa zetoti ziyaqhubeka zisisiseko ngenxa yokuqina kwazo, ukusebenza kakuhle kweendleko, kunye nokukwazi ukugcina iziqulatho. Inkqubo yokwenziwa kwezi toti, nangona kunjalo, iye yavela ngokumangalisayo kule minyaka idlulileyo, kunye nenkqubela phambili kwitekhnoloji eyenza imveliso isebenze ngakumbi kwaye ichaneke. Embindini wokwenziwa kwetoti yanamhlanje zizinto eziphambili zezixhobo ezinje ngoomatshini bokuwelda bomzimba ozenzekelayo, iimela zokusika zetinplate, kunye noomatshini bokusika abazenzekelayo, abaqinisekisa imveliso egqityiweyo ekumgangatho ophezulu.

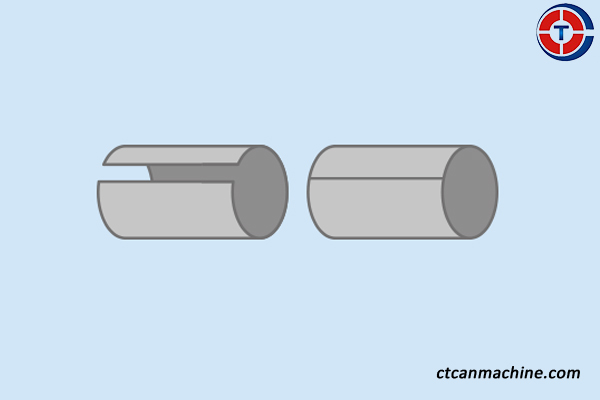

Olunye lolona phuhliso lubalulekileyo kumgca wokuvelisa wetoti ngumatshini wokuwelda umzimba. Aba matshini badlala indima ebalulekileyo ekujoyineni umzimba we-cylindrical wetoti ngokuwelda imithungo yentsimbi, ngokuqhelekileyo besebenzisa imathiriyeli efana ne-tinplate, ipleyiti yentsimbi, ipleyiti yechrome, ipleyiti enezinki, kunye nentsimbi engatyiwayo. Oomatshini bokuwelda banamhlanje abasuka kubavelisi abafana ne-Changtai Intelligent benzelwe isantya kunye nokuchaneka, ukwandisa umthamo kunye nokunciphisa ukubakho kweziphene. Aba matshini bacwangciswe ukuba badibanise i-seams ngokuchaneka okuphezulu, okubalulekileyo ekuqinisekiseni ukunyaniseka kwesakhiwo setoti.

iingenelo eziphambili

Iumatshini wokuwelda umzimba ozenzekelayoibonelela ngeengenelo ezininzi eziphambili eziyenza ibe sisixhobo esibalulekileyo kwimveliso yanamhlanje:

● Ukunyuka kweMveliso yoMveliso: Oomatshini be-welding ngokuzenzekelayo banciphisa kakhulu ixesha elifunekayo ukujoyina amaphepha esinyithi, ukwandisa isantya esipheleleyo senkqubo yokuvelisa. Oku kwenza abavelisi bavelise umthamo omkhulu weetoti ngexesha elifutshane, ukuphucula ukusebenza kakuhle kunye nokuhlangabezana nemfuno ephezulu.

● Ukuchaneka okuPhakamileyo kunye nokuNxibelelana: Aba matshini benzelwe ukuwelda okuchanekileyo kwee-metal seams, ukuqinisekisa ukudibanisa kunye ne-uniform weld kuzo zonke iitoti. Ukuchaneka koomatshini be-welding ngokuzenzekelayo kunceda ukuphelisa iziphene ezifana ne-seams ebuthakathaka okanye engalinganiyo, enokuthi idibanise ingqibelelo yesakhiwo samathini.

● Iindleko eziNcitshisiweyo zeMisebenzi: Ekubeni le nkqubo izenzekelayo, imfuneko yomsebenzi wezandla iyancipha kakhulu. Oku akupheleli nje ekunciphiseni iindleko zabasebenzi kodwa kwakhona kunciphisa impazamo yabantu, okukhokelela kumgangatho wemveliso ongaguqukiyo. Abaqhubi bafuna kuphela ukubeka iliso kumatshini, okunciphisa umngcipheko weempazamo kunye neengozi.

● Ukusebenza kakuhle kwamandla: Oomatshini be-welding banamhlanje bahlala beyilwe kunye neempawu zokulondoloza amandla eziphucula ukusetyenziswa kwamandla ngexesha lenkqubo ye-welding. Oku kunciphisa iindleko zokusebenza kwaye kufake isandla kwiindlela zokwenziwa kwemveliso ezizinzileyo.

● Ukuphuculwa koLawulo loMgangatho: Ngeempawu eziphambili ezifana nokuhlola i-automated seam kunye neenkqubo zokulawula, aba matshini banokubona iziphene ngexesha lokuvelisa, ukuqinisekisa ukuba kuphela iitoti ezihlangabezana nemigangatho yomgangatho ziqhubela phambili kwinqanaba elilandelayo lenkqubo. Oku kubeka iliso okuqhubekayo kwandisa umgangatho opheleleyo wemveliso egqityiweyo.

● Iindleko zokuLondoloza okuPhantsi: Uninzi lwezixhobo zokuwelda ezizenzekelayo zakhiwe ngezinto ezihlala ixesha elide, ezikumgangatho ophezulu ezifuna ukugcinwa okuncinci rhoqo xa kuthelekiswa nemodeli endala, yezandla. Ukuxilonga okuzenzekelayo rhoqo kukwanceda ukuchonga imiba enokubakho ngaphambi kokuba ikhokelele kwixesha eliphantsi okanye ukulungiswa kweendleko.

● Ukudityaniswa nezinye izixhobo ze-welding: Aba matshini be-welding banokudibaniswa ngokungenamthungo kumgca wokuvelisa ozenzekelayo, osebenza ngokubambisana nabanye oomatshini abafana noomatshini bokusika, oomatshini bokusika, kunye nezixhobo zokugquma. Oku kudala inkqubo yemveliso elungelelanisiweyo, esebenzayo enciphisa imiqobo kwaye iphucule imveliso.

● Ukuguquguquka kokwenziwa ngokwezifiso: Uninzi oluzenzekelayo lwemishini ye-welding yomzimba inokulungelelaniswa ukuze ihambelane nobukhulu obuhlukeneyo kunye neenkcukacha. Oku bhetyebhetye kwenza kube lula ukulungelelanisa imveliso eqhutywayo ukuhlangabezana neemfuno ezithile zemarike, nokuba yeyebhetshi encinci okanye imveliso enkulu.

Ukuzenzekela koomatshini bokuwelda umzimba babonelela ngoluhlu lweenzuzo eziphucula ukusebenza kakuhle, ukunciphisa iindleko, kunye nokuphucula umgangatho wemveliso, kubenza babe yinxalenye ebalulekileyo kwimveliso yanamhlanje.

Emva kwenkqubo ye-welding, ii-sheet sheets zixhomekeke kwi-slitting ukuvelisa imicu emincinci eya kwenza imizimba ye-cylindrical. I-tinplate yokuqhawula iimela ziyimfuneko kule nyathelo, ukusika amacwecwe esinyithi ngokuchaneka okuchanekileyo. Umgangatho wale mitshetshe, ehlala yenziwe ngezinto ezikumgangatho ophezulu ezifana ne-carbide, ichaphazela ngokuthe ngqo ukuchaneka kwenkqubo yokuqhawula kunye nomgangatho opheleleyo wemizimba yeetoti. Iinkampani ezifana ne-Huxin Cemented Carbide zisebenza ngokukhethekileyo ekuveliseni ezi blade ze-carbide, ezaziwa ngokuba bukhali kwazo, ukuxhathisa ukunxiba, kunye nobomi obude.

Ngokudibeneyo, obu bugcisa bulungelelanisa inkqubo yemveliso yetoti, evumela abavelisi ukuba bavelise iitoti ezikumgangatho ophezulu ngesantya esikhawulezayo. Njengoko imfuno yabathengi yokupakishwa okuthembekileyo nokuzinzileyo ikhula, ishishini liyaqhubeka nokutyala imali koomatshini bokusika abaqinisekisa ukusebenza kakuhle kunye nokuchaneka. Ukusuka kwiwelding ukuya ekunqunqweni nasekuchebeni, ukusetyenziswa kwezixhobo ezikumgangatho ophezulu kwitoti yokwenziwa kwetoti kuvula indlela yexesha elitsha lezisombululo zokupakisha.

China umboneleli ophambili weIziqwenga ezi-3 zeToti yokwenza umatshinikwayeIAerosol inokwenza umatshini.

Changtai Intelligent Equipment Co., Ltd.inamava okwenza i-Factory Machine.Kubandakanya ukwahlula, ukubumba, ukugoba, i-flanging, i-beading kunye nokuthunga, zethu ukwenza iinkqubo zibonakalisa i-modularity yezinga eliphezulu kunye nekhono lenkqubo kwaye zilungele uluhlu olubanzi lwezicelo,

Ngokukhawuleza, ukulungiswa kwezixhobo ezilula, zidibanisa imveliso ephezulu kakhulu kunye nomgangatho wemveliso ephezulu, ngelixa unikezela ngamanqanaba aphezulu okhuseleko kunye nokhuseleko olusebenzayo lwabaqhubi.

Yazi ngakumbi

Ukwazi ngakumbi malunga namaxabiso kunye neenkonzo, nceda cofa apha>>>Qhagamshelana nathi

--------

Ukwazi ngakumbi malunga neNkampani yethu, nceda ucofe apha >>>Ngathi

--------

Ukwazi ngakumbi malunga neepotfoliyo zethu, nceda ucofe apha>>>Iimveliso zethu

--------

Ukwazi ngakumbi malunga ne-AfterSales yethu kunye nabanye abantu ababuza imibuzo, nceda ucofe apha>>>FAQ

--------

Jonga iimveliso > > >Ikhonkco: Uyakwazi ukwenza izixhobo...

Ixesha lokuposa: Jun-12-2025